Chromodising

Chromodising

Chromodising is a surface treatment process that combines chromating and anodising to enhance the corrosion resistance, durability, and appearance of aluminum and its alloys. This hybrid technique is widely used in industries requiring robust and long-lasting finishes, such as aerospace, automotive, and construction.

We have pre-treatment line for aluminium metal parts chromodising.

| Technical Data & Key Strength of plant | |

|---|---|

| Plant type | PLC based automatic PT Oxsilane line with conveyorised powder coating facility |

| Tank Size | L-3000mm x W-1250mm x H-1375mm |

| Oven cutout size | H- 2750mm x W-2600mm x L-6500 |

| Plant Area | 40000 Sq feet |

| Volume | 5000 Ltrs |

| Plant Capacity | 3000 Sq mtr/day |

| Conveyor length | 12 Mtrs |

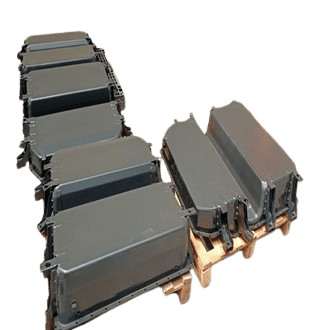

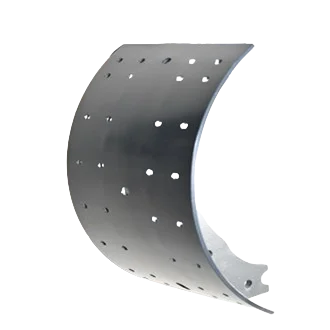

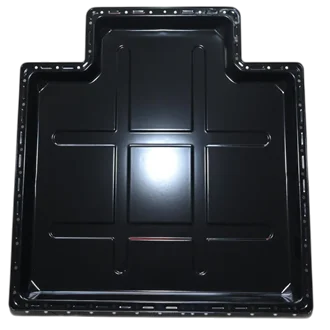

Products

Looking For A Trusted Supplier In CED & Powder Coating

At Tirupati Engineering, we aim to build long-term partnerships with our clients in order to ensure a world-class, integrated supply chain. We strive to consistently meet extremely high standards for quality, delivery, cost and customer satisfaction for our clients.